Home Services

Our Services

For over a hundred years, Sheboygan Paint Company has been helping OEMs and refinishers overcome whatever paint line challenges they encounter. From formulation to application to performance, we find the solutions that work best for you and deliver precisely what you need.

Technical Development

You have specific and perhaps highly demanding product coating needs. We have coating scientists who are excited to solve even the toughest challenges. Our coating scientists draw on paint chemistry expertise and knowledge of applications to formulate solutions for the most challenging product coating requirements. With fully staffed technical departments at our manufacturing facilities in Wisconsin and Georgia, we can perform product research and develop custom coating formulations that precisely meet your needs.

Our reputation as the problem solver stems from the continuous innovation and adaptation of new technologies with which we fulfill ever-evolving product industrial coating demands.

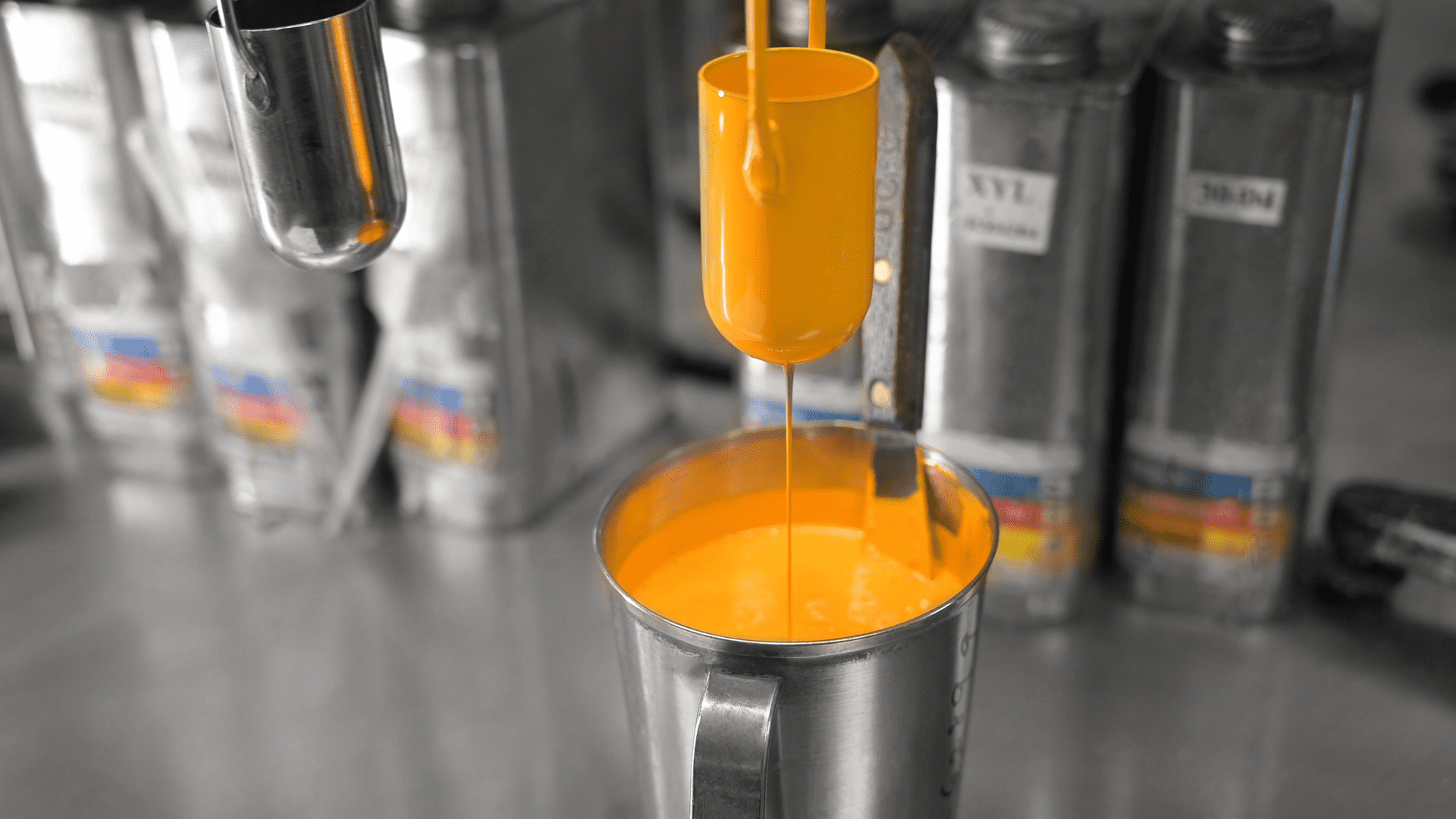

Precision Color Matching

Need an exact paint color match? No problem. Sheboygan Paint Company specializes in precise color matching for industrial product coating. Whether you have an existing product color to be matched, material of a certain color that you need paint to match, or a specific sheen you want matched on a known color, we can accommodate you. Precision color matching is conducted by coating scientists within our technical labs. Our teams use state-of-the-art technology, including highly sensitive spectrophotometers, robust color matching software, digital gloss meters and ISO 3664 compliant light booths, along with experienced eyes to determine the perfect color match.

Our technical department will formulate a sample batch of the specified color for testing. With a verified match, our manufacturing staff will scale up the production run to produce the quantity of paint you need.

Product Quality Testing

Our quality control department conducts stringent testing to assure our product precisely meets your needs before it is shipped.

Quality control takes place from start to finish. All raw materials used in formulating and manufacturing our protective coatings are validated with respect to purity and quality. Within our development lab, custom formulations are assessed for their physical and performance properties based on the purpose and application of your particular coating need. The lab formulation we create for you is tested on small-scale equipment similar to equipment used in your production process. And our staff performs a complete testing regiment on each trial batch to ensure that the scaled-up batch conforms to the test results of the final lab trial. For the full production run, QC testing is conducted during and immediately after manufacturing to verify our products’ physical and performance quality specific to your application.

Physical Testing

- Grind (Fineness of Dispersion)

- Hue / Tint Strength

- Opacity

- Gloss / Flatness

- Viscosity

- Moisture Resistance

- Drying Time

- Rub Up

- Density

- Non-Volatile Residue

- pH

- Heat-Aged Stability

- Low Temperature

- Coalescence

- Application Properties

Performance Testing

- Hiding Power

- Sag

- Leveling

- Adhesion

- Hardness

- Flexibility

- Impact

- Scrub Resistance

- Tensile

- Temperature Resistance

- Chemical Resistance

- Permeability

- UV/Weathering Resistance

Our Quality Policy

Sheboygan Paint Company’s Quality Policy is committed to the following:

- A system of quality management that provides a framework to establish, review and meet high quality objectives;

- A product and service that precisely fulfills customer requirements;

- A continuous improvement process that ensures the effectiveness of the Quality Management System and continued business success.

Responsive Technical Support

When you have a paint line problem, call on us to solve it — right at your paint line, when that’s required. We have coatings application experts ready to provide technical and engineering support that gets your coating process operating the way you need it. Call on our Swift Technical Unit (STU) to research and troubleshoot any paint line performance, environmental or safety related challenge you encounter. Our team responds with immediate urgency to solve problems for all aspects of industrial wet coatings processes. Sheboygan Paint Company also maintains and continuously updates Safety Data Sheets, stays alert of regulatory changes and relays vital technical and regulatory information to our customers.

Expedited Shipping

Sheboygan Paint Company delivers throughout the contiguous U.S. Since the Department of Transportation considers paint a hazardous material, all paint shipments must be sent via ground transportation. How urgent is your delivery need? We respond by choosing the most reliable freight carrier for the fastest delivery.

We’re always ready to provideoutstanding Customerized service.

Sheboygan Paint Company can solve whatever wet paint application and performance challenges you have, so that you efficiently coat to produce beautiful and durable product surfaces.